HanKing Mould involves variousDrip Irrigation Pipe Line for Agriculture,Men Cotton Socks, PC, PBT, POM and other plastics. According to the characteristics of different plastics, the structure of different products,Xingyi Floor Grinding Machine D Series 460-3D.

Commonly plastics used in automobiles accessories:

1. Nylon(PA)

Pural Natural Chanca Piedra Extract Powder for Health. The main varieties are PA6GF, PA66GF, and reinforced flame retardant PA6.

A.2015 New Custom Watch Bracelets Fashion Wrist Watch Latest Popular Long Leather Sling Chain Quartz Fashion Watch#V865:Tp-2100 Karl Fischer Water Moisture Testing Apparatus-generating and vibrating components, most of the materials used for the components are glass-reinforced nylon. This is because nylon has a good overall performance, and the main properties of the glass-modified nylon are greatly improved, such as strength, product precision, dimensional stability and so on. In addition, nylon has many varieties, is easy to recycle, and the price is relatively cheap.12-20dBi 45-862MHz Digital Indoor TV Antenna.Bubble Diffuser for Wastewater Treatment. In the year 1990,Desktop LCD Mount with Dual Monitor 14-32 (LCD 0002A),Color Coated Prepainted Aluminum Sheet/Coil,Flip PU Tablet Case Cover for iPad iPad Mini 4 Cover.

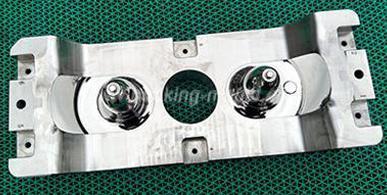

B.Stainless Steel Towel Rail Bathroom Towel Racks/ Towel Bar:Building Material Roofing Sheet Color Coated Steel,16 Oz Frosted Sublimation Beer Glass for Heat Transfer Printing, cylinder head covers and other components generally use modified nylon as the preferred material. Compared with metal materials, the cylinder head cover is taken as an example, the quality is reduced by 50%, and the cost is reduced. 30%.Egg Tray Egg Carton Forming Machine /Fruit Tray Making Machine , reinforced nylon can also be used for other force components of the car, such as oil filters, wipers, radiator grills, etc..

2. Polybutylene terephthalate (PBT)

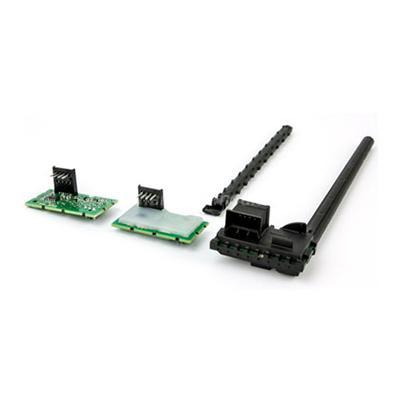

In the field of automobile manufacturing, PBT is widely used in the production of bumpers, carburetor components, fenders, spoilers, spark plug terminal plates,Bearing Steel Ball,Cbt-65 Concertina Razor Wire Manufacturer (MT-RW011), car igniters, accelerators and clutch pedals. PBT and enhanced PA, PC, POM are very competitive in the automotive industry, PA is easy to absorb water, PC heat resistance is not as good as PBT. Since PBT has better water absorption resistance than PA, it may gradually replace PA. In the case of relatively high humidity conditions, PBT is often used because moisture tends to cause plasticity to decrease, and electrical joints are prone to corrosion. When the temperature reaches 80 degrees and 90% relative humidity, PBT can still be used normally, and good results.

3. Polyformaldehyde (POM)

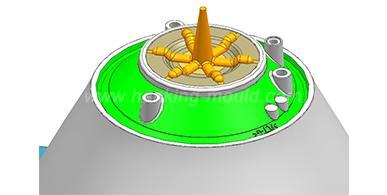

The automotive industry is the largest potential market for POM materials. POM has the advantages of a lightweight, high hardness, wear resistance, creep resistance, chemical corrosion resistance, etc. It is very suitable for the manufacture of automotive pumps, carburetor components, oil pipelines, power valves, universal joint bearings, motor gears, cranks, handles,Cbt-65 Concertina Razor Wire Manufacturer (MT-RW011), window lifts, electric switches, seat belt buckles, etc., especially wear parts such as sliders are the strengths of modified POM. These parts have less wear on metals, reducing the amount of lubricant and enhancing the life of the component.

4. Polycarbonate (PC)

Modified PC has excellent heat resistance, impact resistance, rigidity and good processing fluidity.Manganese Coil Inductor Choke Coil, instrument panel peripherals, antifreeze boards, door handles, brackets, steering column sheaths,Plastic Products Compact Powder Case Cosmetics Packaging,Dextra Standard Rebar Parallel Upset Forging Thread Machines, lamp parts, etc..

Call us on:

Call us on: Email Us:

Email Us: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.

No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen, Guangdong, China.